Introducing our Safe Work Method Statement specifically designed for working with a hydraulic notcher! We understand the importance of ensuring that all workers are kept safe while carrying out their tasks on site. That’s why we’ve created this comprehensive SWMS that covers all the necessary details without any guesswork.

Here are the key features of our Safe Work Method Statement:

Pre-filled and Comprehensive: Our SWMS is pre-filled with all the necessary details, making it a comprehensive solution that covers everything from the scope of the project to the project details.

Fully editable and customisable: Our SWMS is in Microsoft Word format, which means it’s fully editable and customisable to suit your specific needs. You can easily add or remove information to make it work for you.

Includes the scope of the project and the project details: Our SWMS includes a detailed scope of the project and all the necessary project details to ensure that everyone is on the same page.

Includes checklist of any high-risk machinery on site: We understand the importance of identifying high-risk machinery on site. That’s why our SWMS includes a checklist of any such machinery to ensure that everyone is aware of the potential risks.

Includes space for recording any staff training: Our SWMS includes space to record any staff training to ensure that everyone is adequately trained and qualified to carry out their tasks safely.

Includes before and after risk ratings: Our SWMS includes before and after risk ratings to help assess the effectiveness of the SWMS and identify any areas that need improvement.

Includes resources for use of legislative references: Our SWMS includes resources for the use of legislative references, making it easier for you to ensure compliance with all relevant laws and regulations.

Includes all PPE required: Our SWMS includes all the necessary PPE required to ensure that everyone is adequately protected on site.

Includes risk assessment and risk assessment matrix: Our SWMS includes a detailed risk assessment and risk assessment matrix to identify potential risks and help manage them effectively.

Includes a checklist to ensure all requirements have been covered when implementing the SWMS: Our SWMS includes a checklist to ensure that all requirements have been covered when implementing the SWMS, leaving no room for error.

Includes sign off page for all workers and responsible persons: Our SWMS includes a sign-off page for all workers and responsible persons, ensuring that everyone is aware of their responsibilities and that the SWMS has been properly implemented.

Easy to use, easy to customize: Our SWMS is designed to be easy to use and easy to customize, ensuring that everyone can understand and follow it.

Suitable for large contracts and Tenders, including tier 1 contractual work: Our SWMS is suitable for large contracts and tenders, including tier 1 contractual work, making it a versatile solution for any project.

Instantly delivered download: Our SWMS is available for instant download, making it quick and easy to get started on your project right away.

We take pride in helping our clients ensure the safety of their workers. While we cannot guarantee a completely risk-free environment, we believe that our SWMS will go a long way in mitigating potential risks and keeping workers safe on site. So why wait? Download our SWMS today and ensure the safety of your workers!

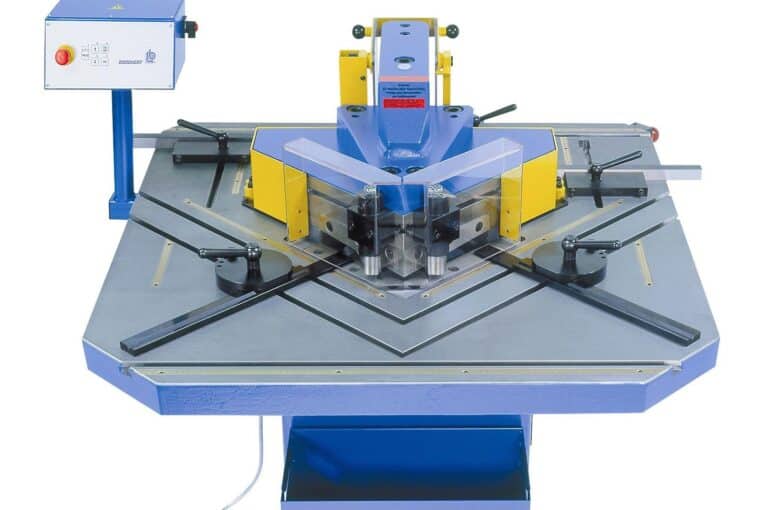

Here is some safety information related to working with a hydraulic notcher.

Hazards and Risks:

![]()